| Name | Contact | |

|---|---|---|

| Electronics Workshop in Campus-Navi | S2|05 |

|

J

| Mohamad Hesham Jenbaz B.Sc. | mohamad.jenbaz@pkm.tu-... +49 6151 16-21535 S2|05 106 |

|

E

| Ibrahim El-Idrissi | ibrahim.elidrissi@pkm.tu-... +49 6151 16-21534 S2|05 104 |

|

S

| Dipl.-Ing. (FH) Florian Scheer | +49 6151 16-21534 S2|05 107 |

|

W

| Christine Weber | +49 6151 16-21534 S2|05 104 |

|

W

| Klaus Weber Head of Electronics Workshop | klaus.weber@physik.tu-... |

Institute for Condensed Matter Physics

Infrastructure

The IPKM research infrastructure includes the electronics and precision mechanics workshops, IT support and the helium liquefaction plant. For information on the labs and equipment of our groups, please refer to the group websites.

Electronics Workshop

The team of the IPKM's electronics workshop maintains and looks after the electronic equipment in the laboratories and, to some extent, the building technology. In addition, user-specific devices are developed together with researchers and the precision mechanics workshop.

The workshop integrates theory and practical application by facilitating dual training: We work in concert with local vocational schools to exercise theoretical concepts through individual projects.

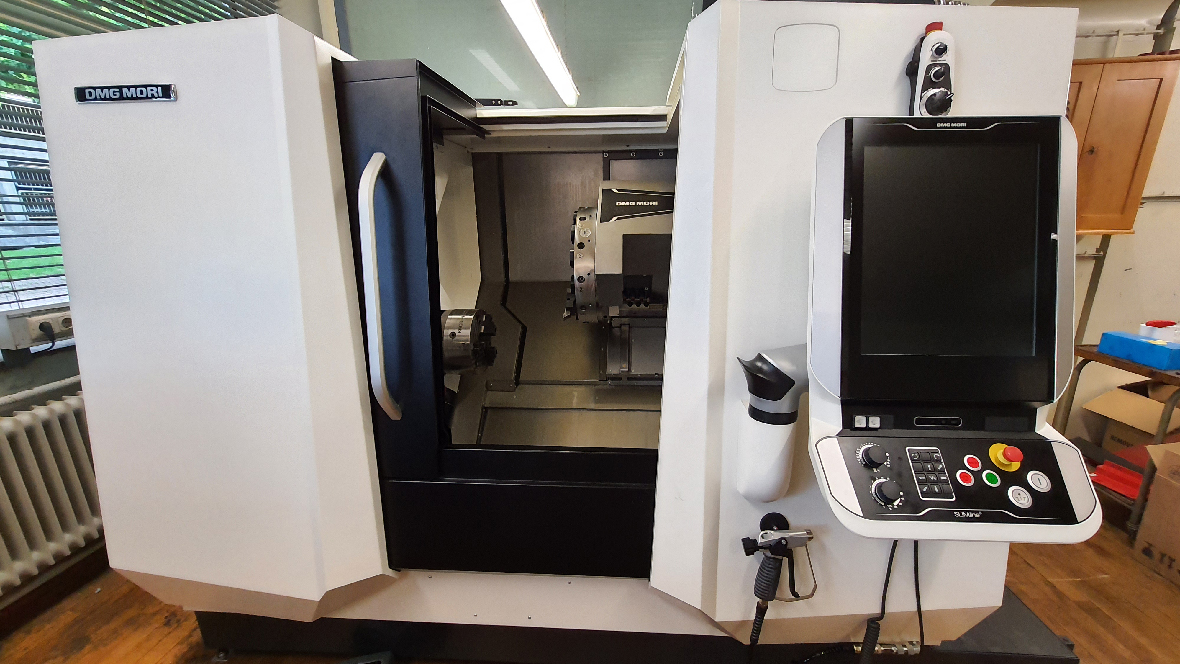

Precision Mechanics Workshop

Our team carries out all precision mechanical work and repairs for the institute's experimental working groups. The workshop is partly involved in the development of apparatuses and precision mechanical devices in teamwork with the group technicians of the institute.

Furthermore, apparatuses for the lectures and the lab courses are provided.

IT support

We take care of the central IT infrastructure at the IPKM. In addition to support in the offices and laboratories, we also offer support and provision of various network services.

Helium liquefaction

A central helium facility for the entire TU Darmstadt has existed for over fifty years and is traditionally located at the Institute for Condensed Matter Physics (formerly Solid State Physics).

After several predecessor plants from ADL, Philips and Linde, the institute has been operating a TCF 20 liquefier from Linde since 1995. The plant was modernised in 2018 by the company Vorbuchner.

Building services

| Name | Working area(s) | Contact | |

|---|---|---|---|

|

G

| Thomas Geistlinger-Miehle | hv-mpa-nord@zv.tu-... +49 6151 16-24975 S2|07 016 | |

|

H

| Andreas Hönig | hv-mpa-nord@zv.tu-... +49 6151 16-24975 S2|07 016 | |

|

K

| Guido Kikowatz | hv-mpa-nord@zv.tu-... +49 6151 16-24975 S2|07 016 | |

|

L

| Mario Lo Stocco | hv-mpa-nord@zv.tu-... +49 6151 16-24975 S2|07 016 |